Process manufacturing could also be a way of constructing products using recipes or formulas. The raw components that structure an item often cannot be detached or far away from the ultimate product after production. Process manufacturing relies on the flow of sequential steps, with the completion of 1 step resulting at the beginning of the subsequent step. Process manufacturers often believe tracing and scheduling tools and software to require care of peak operational efficiency.

Process manufacturing may be associated with:

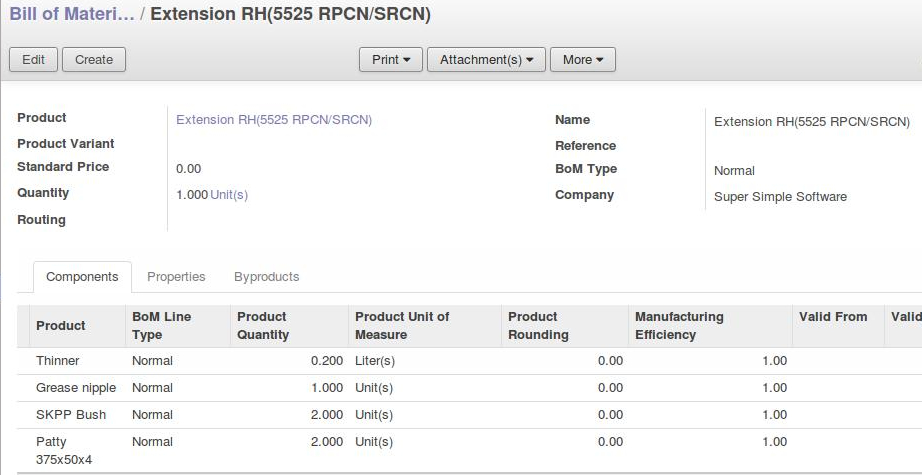

Recipes and Formulas

Mixes and Blends

Variable Ingredients

Identification of Parts by Attributes

Measurements of Weight or Volume

And, SuperSimpleERP has it all covered up. A software that centralizes your daily business processes into a master database capable of synchronizing key elements related not only to the work but also to finances, customer relationship management (CRM), warehouse management, distribution management and human capital management (HCM). The mixing of those critical functions can boost productivity and increase revenue.

How does SuperSimpleERP benefit you?

Read More